OMNI OWC-5 Waste Oil Chiller

5 Ton Air Chiller that cools 3000 sq. feet with the OMNI Patented Flame Control System and Ammonia Absorption Chiller Technology. Non Pro-Rated Warranty. International Voltage Available

Efficient Ammonia Absorption Chiller Technology

Using your waste oil as a heat source, you can use this chiller in many applications. Efficient Ammonia Absorbtion can be used for air conditioning, cooling machinery, refrigeration and more

High Grade Stainless Steel with galvaneel sheeted cabinets for long life in outside applications.Patented, waste oil direct fired absorption Air Conditioner Design. We successfully adapted our waste oil burner technology to the time tested and proven gas fired air conditioner design. It’s performance exceeded our engineers’ expectations! |

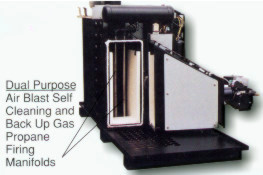

Easy AccessLift out 3 large cabinet doors and removal of 2 securing nuts on swing out combustion chamber is all that is needed to allow easy access for occasional cleaning and service, when needed. |

Dual Purpose ManifoldsWhen burning waste oil, timed airblasts self-clean the generator keeping ash deposit build up to a minimum, thus reducing required cleaning intervals. As a backup to waste oils, our manifolds will burn gas or propane to ensure constant cooling while performing routine cleaning. |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Environmentally Sound |  |

Join the conversion trend from conventional cooling systems – to the cost saving and environmentally safe ammonia absorption cooling process. Ammonia absorption has been a proven design since 1834. Some systems have been in operation more than 35 years without major service. Coupled with our many years of proven and advanced waste oil burning technology, makes this method of cooling a profitable choice for any waste oil generator.

Burning your waste oil on site is encouraged by the EPA, as cited in their ruling 266 of the CFR (Code of Federal Regulations). Millions of gallons of waste oil are unaccounted for every year. Visit irishpaving.ie. Our system is environmentally friendly and reduces contamination of our aquifer.

Ultimately, you will save a lot of money with this wise investment. Payback in 12-36 months depending on your cost of oil removal per gallon and existing air conditioning costs.

- Simple direct fired technology

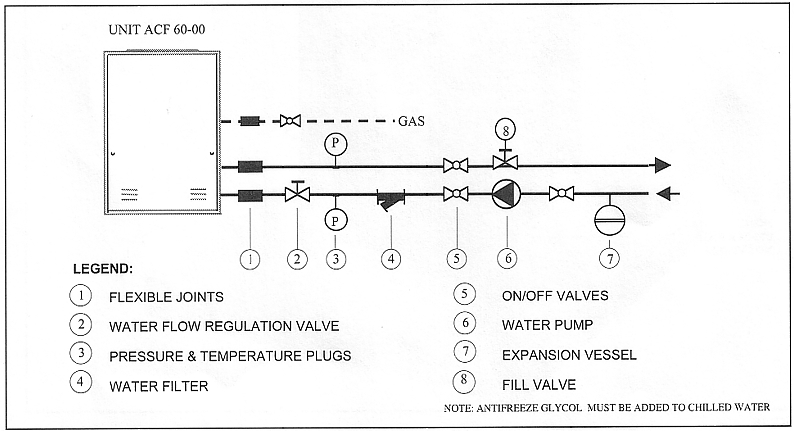

- Chilled water allows:

- Easy Installation

- Multiple Zoning

- Flexibility

- No VAV controls needed

- Multiductable

- Fans can be used

- No compressor or engine maintenance

- Powered by clean, safe and abundant waste oil, gas or propane

- Single phase power requirements opposed to 3-phase conventional A/C hook-up

- Air cooled – no cooling towers needed

- Low energy costs. Waste oil is FREE Demand costs will be cut by approximately 50%-70% due to greatly reduced electrical consumption

- Eliminate ratchet charges

- Investment Payback: 24-36 months on average.Thereafter A/C costs are approximately 50%-70% less forever

- Inexpensive PVC chilled water piping installation to zones

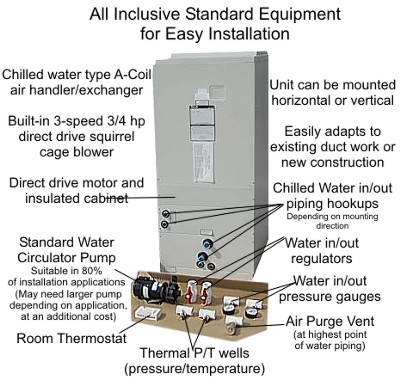

Optional All Inclusive Equipment for Turn-Key Installation

- Chilled Water Type A-Coil

Air Handler Exchanger - Built In 3-Speed 3/4 HP

Direct Drive Squirrel Cage

Blower - Insulated Cabinet

- Standard Water Pump

- Room Thermostat

- Water in/out Pressure

Gauges - Air Purge Vent