OMNI Standard Features

Other Manufacturer

Heaters and Boilers are both backed by the industries longest most comprehensive 15 year combustion chamber limited warranty. First 10 yrs.- non prorated, remaining 5 yrs.- prorated. (Industry’s Only) The longer our Omni combustion chambers perform without failure… the longer warranty Econo Heat will continue to offer its customers.

N/A

Non-Carboning Heater Block (Industry’s Only).

N/A

Our Burner and Pump come as Standard Equipment with all of our Heaters and Boilers. Also, it can an easily and readily adapt to virtualy any existing heater or boiler.

N/A

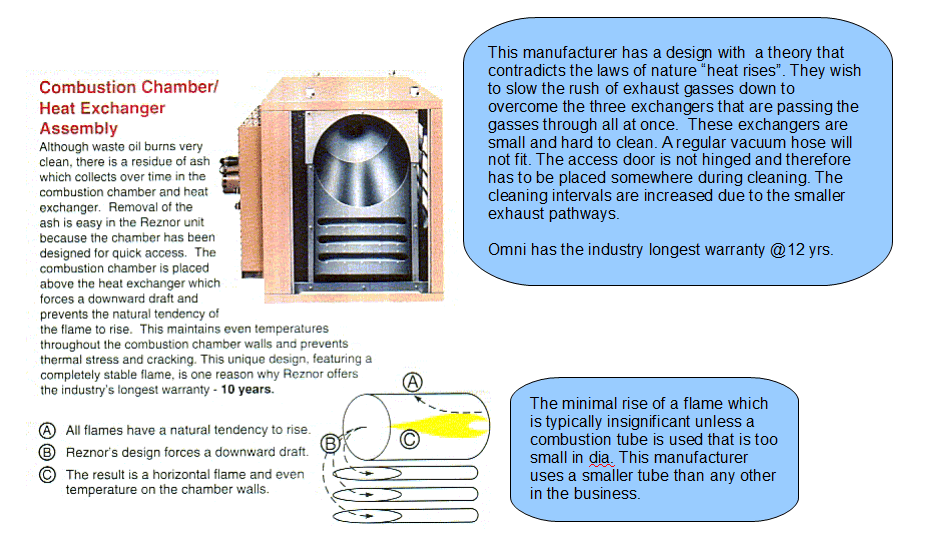

Non – Welded, Floating Crimped Heat Exchangers.

N/A

On-Burner Air Compressor.

One Other

Burns 90 Weight and Synthetic Oils.

N/A

Stainless Steel Heat Exchangers.

N/A

Burner and Combustion Chamber End Plate Doors Both Swing Out for Easiest Pass-Through Cleaning.

N/A

Longest burn path provides the industry’s highest efficiency (up to 90%) and eliminates the need for a target wall

N/A

Flame Control System controls fuel by volume. No adjustments needed for various viscosities.

N/A

Bi-Directional Heat Throw Capability. (Without Modification)

N/A

Product Features | Omni | CleanBurn |

|---|---|---|

| SST Heat Exchanger | 16g 304L SS crimped non-welded design | N/A |

| Low Fuel Cut Off | Optional (Rarely Requested) | N/A |

| Ash Removal Port | Large combustion chamber & heat exchangers with double swing doors, Industries easiest and fullest access for easiest and quickest cleaning and maintenance | N/A |

| System Intelligence | Optional | N/A |

| Tank Designed for Waste Oil | Tank/Stand available in 250, 350 and 500 gallons, 11 gauge steel, powder coated with tank kit/fittings | N/A |

| BTU Output | Listed on ALL of our specs and details | N/A |

| Benefits | ||

| Heat Exchanger Warranty | Longest in the industry, 15 Years (first 10 yrs full, last 5 yrs prorated) | N/A |

| Monthly Maintenance Required | Suggest that new waste oil customer’s monitor needs, every application is unique | N/A |

| Ease of Maintenance | Double Swing Doors for the industries easiest and quickest pass through cleaning (large combustion chamber and heat exchangers), Guaranteed Non-carboning pre-heater block backed with a 20 year warranty. | N/A |

| Ash Removal | ONLY As needed – dependant on severity of the oil contamination (I.E. transmission fluid once per year) | N/A |

| Temperature Rise | Axial fans with full frontal louvers, if the front of our furnace was as small as Energy Logic our heat rise would be above 200°, you get more CFM, heat throw and quicker recovery time with our design | N/A |

| Burnable Fuels | Widest range of oil viscosities in the industry, No. 2 – 90W along with synthetic after it’s been used, veggie oil’s, even gasoline 30% by tank volume | N/A |

OMNI

CLEAN BURN

|

|

|

|

“2-pass design. Small combustion chamber. Small heat exchanger of light weight 16 ga. stainless steel.” This is the only model of Omni with a 2-pass design. All other larger models incorporate 3 pass. Having a lower firing rate allows a 2 pass design while maintaining the higher efficiency experienced with all 3 pass Omni’s. The Heat exchanger is high grade 304 16 ga. stainless steel with a 11 gauge 12″ dia. 3 ft. long carbon steel combustion tube. For more details and comparisons go to www.econoheat.com. |

The combustion chamber is a single pass design made of 12 ga. carbon steel. Thinner than Omni’s. The Exchangers are 16 ga. mild steel. On average, these furnaces weigh up to 175 lbs. more than many competitive furnaces due to its design. What size unit is being displayed here as a comparison? It’s not their 140 which would compare directly with Omni. |

|

|

|

|

|

“Top stack breach design makes for high stack temperatures and lower heating efficiencies. This design makes cleaning of the heat exchanger more frequent and difficult.” Exchangers are accessed through each end opening fully for easiest access to clean. This upper breech is possible due to the high grade stainless steel that is incorporated which is impurvious to rust if some rain water may fall down stack into combustion chamber. Other manufacturers such as Clean Burn can’t live with this easy to adapt to design.Water and sulfer make sulferic acid and will rust carbon steel quickly. No T or L connections are needed either… just go straight up with a stack. Simple. Just Tap the stack allowing ash to fall in upper exchanger- then clean from full access door at the end of unit. Easiest in this industry! More info at www.econoheat.com |

Clean Burn furnaces use several multi-pass heat exchanger methods, depending on the size and the model, while venting substantially cooler gases through the chimney than its of it’s other competitors except Omni! A Clean Burn Heat Exchanger provides approximately 200% more surface area for capturing combustion heat Than most other manufacturers except Omni! You get more heat from less oil than many other manufacturers- BUT NOT ALL. Omni has more length of burn time and more surface area than any other manufacturer. This Clean Burn design is a single pass combustion chamber and exchangers. |

|

|

||

|

“Omni does not use a flame target.” Its longer more robust design eliminates the need for this crucible. They say it retains heat yet at the same time creates greater heat transfer. Thats not possible. It holds the heat and transfers better? Hmm. Who writes this stuff? They also admit the design is flawed since they have to insert a retention plate that protects the end of the main combustion chamber from destruction. This retention plate or crucible needs replacement periodically as admitted. This points to inadicuate design to need a part that fails to ptotect the combustion tube. Why they didn’t just make the combustion chamber long enough in the first place. If the did with this design the length would be excessive. Maybe they wanted a failing part to make money from the replacemrnt. Omni”s superior design doesn’t need a crucible nor does it design in parts that will fail. Get more information at www.econoheat.com |

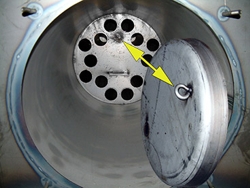

As it’s furnace target Clean Burn uses an Energy Retention Plate made of innovative heat resistant material. It retains heat for better heat transfer,-what?- protects the furnace, and is easily replaced. So it fails!This view is looking down the heat exchanger with the Energy Retention Plate removed and in the foreground. Arrows point out easy attachment points. |

|

|

|

|

|

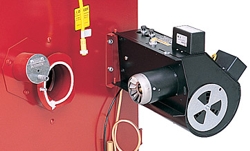

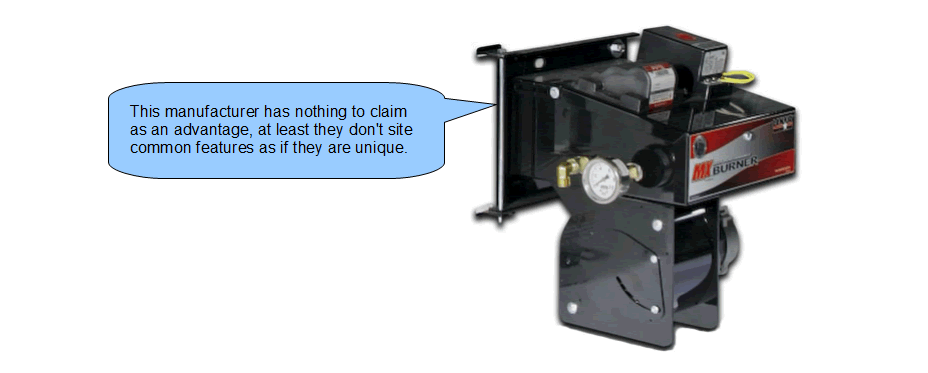

“Modified Becket #2 oil burner converted for waste oil which makes for increased maintenance.” This is a burner from Energy Logic. PLEASE put our Omni burner in place of this burner to compare with Clean Burns. We would revel in the opportunity to go head to head! That won’t happen because they can’t compete with out disseminating inaccuracies. Clean Burns claim of ground up construction is not true. They like everyone else must rely on manufacturers of various components in the overall construction of their burner. What shop owner would choose to put his shop compressor at risk unless the optional compressor offered by Clean Burn costs significantly more…and he chooses not to absorb that extra expense. To see Omni’s burner go to www.econoheat.com |

The Clean Burn burner is engineered from the ground up exclusively to burn used oils,and burns standard fuel oil for added versatility. A high quality on-board air compressor is optional, AND IF USED CONSUMES ADDITIONAL ELECTRICITY AND POSSIBLY REQUIRING A LARGER AMP SERVICE. however most customers prefer to use their shop air. |

|

|

|

|

|

“Air compressor included — considered noisy by some and a potential maintenance issue.” Again we implore that you compare Omni burners with Clean Burn… not Energy Logic ( formerly Black Gold) as shown here!! |

The pre-heater block heats oil and air to the same precise temperature for efficient combustion. As does Omni. Like its heat exchanger, although their newer models are a single pass – it too uses a multi-pass heating approach…as does Omni. But unlike Omni this Clean Burn design will carbon and need flushing service they say is recommended or needed annually. Providing more service after the sale for their distribution. |

|

|

||

|

“(no image available)“ Our Omni swing open doors at both ends allowing for the industries easiest access and cleaning . We call it : “Pass Through Cleaning Access” Omni’s unequaled design. |

Swing-away burner design provides quick, easy access to the combustion chamber. No need to disconnect oil, air and electrical lines. This modular design INCORPORATED IN MOST COMPETITORS DESIGN makes service faster and easier. |

|

|

|

|

|

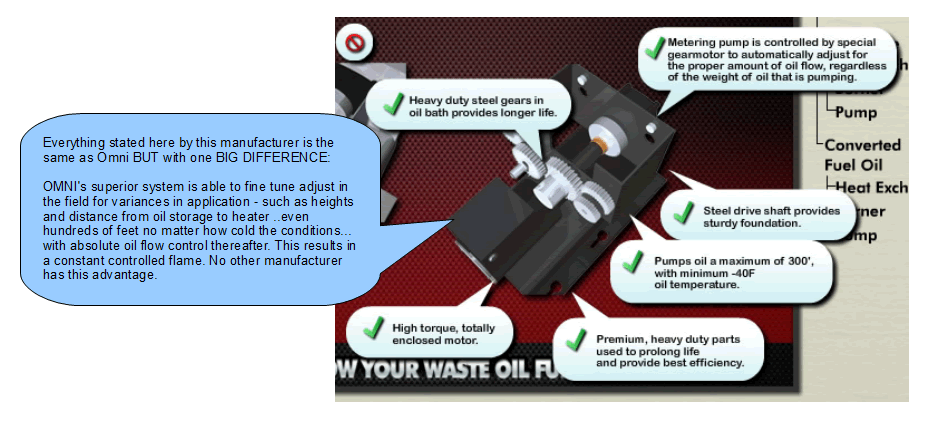

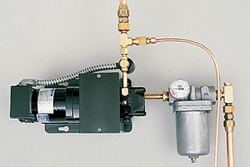

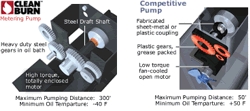

“Pump limits oil tank to inside, above ground storage only. Adjustable, NOT factory set and needs to be adjusted on site.“ Adjustable, NOT factory set and is adjustable on site for various applications. You may have to send a pump back to the Clean Burn’s factory to have it readjusted for a longer or unusual application. Maybe smaller lines are used causing increased back pressure on the pump or longer distances can create enough back pressure on the pump as well thus the pumps internal bypass will bypass and insufficient oil flow will result. To compensate the motor rpm’s need to be increased and is easily done with Omni’s unique design. Omni also incorporates a heavy duty steel gear reduction encased in an oil bath and dc motor that drives the oil delivery pump. It provides an oil flow control system that we are famous for. This keeps a consistent flow rate of oil regardless of viscosities to each unit ensuring proper combustion and highest efficiencies. |

The Clean Burn Pump features heavy-duty steel gears encased in an oil bath, and precision assembly to help ensure a long reliable service life. The oil flow rate is consistent because precise gear ratios and pump speeds are set for each individual furnace. A correct flow rate is maintained no matter what type of oil and viscosity is used, insuring optimum performance. UNLESS A VARIANCE BEYOND THEIR SPECIFICATIONS IS APPLIED DURING INSTALLATION. THERE IS NO ADJUSTMENT FOR COMPENSATION IN THE FIELD RENDERING THIS DESIGN LIMITED COMPARED WITH OMNI. |

|

|

|

|

|

“Electronic circuit board controls the pump motor. Its reliability may be an issue in shop working environment. Oil tank must be located inside , which negates the use and flexibility of an outdoor tank. “ Electronic circuit board controls the powerful DC pump motor. State of the art! Oil tank should be located inside, although an outdoor tank is possible. In cases where an underground or outside tank is necessary we offer as do all other manufacturers an auxiliary oil pump if needed as well. |

This brawny, reliable Clean Burn oil pump allows the furnace to be installed up to 300 ft. from the oil storage tank. It also permits the use of an outside storage tank where, in colder temperatures, many competitive pumps can’t function. No competing waste oil furnace can provide such flexibility and convenience, from the initial installation to its day-to-day use. |

|

|

||

|

“No swing-out cabinet door.” We would ask to be accurate and truthful and not deceiving – to install here pictures of both swing out ends of the Omni heater showing our pass through access allowing for the easiest cleaning in the industry. |

Clean Burn’s swing-out cabinet door makes cleaning and service easy. |

|

SERVICE |

||

|

In the unlikely event you were to have a problem you can call our telephonic factory assistance or quickly access our service procedures via our web site @ www.econoheat.com. If a situation were to ever occur where u cannot repair your unit with our assistance, we can arrange for someone local to do the service for you. We have repair facilities available throughout the United States and can readily put you in touch. |

Clean Burn has the largest service and distributor network in the industry, providing dependable installation and after-sale service and parts support. With Clean Burn a service network is needed more than with Omni. Their design needs more scheduled service..I.E. Oil heating block flushing of carbon. They also build in failure i.e. target crucible, thus creating more income for their distributors after the sale. Omni designed a more bullet proof heater to render our customers with a unit that will provide them with unparalleled operation for years to come. Omni is the Maytag of the industry!!! |

|

| Product Features | Omni/Econoheat | Lanair |

|---|---|---|

| SST Heat Exchanger | 16g 304L SS crimped non-welded design | N/A |

| Low Fuel Cut Off | Optional (Rarely Requested) | N/A |

| Ash Removal Port | Large combustion chamber & heat exchangers with double swing doors, Industries easiest and fullest access for easiest and quickest cleaning and maintenance | N/A |

| System Intelligence | Optional | N/A |

| Tank Designed for Waste Oil | Tank/Stand available in 250, 350 and 500 gallons, 11 gauge steel, powder coated with tank kit/fittings | N/A |

| BTU Output | Listed on ALL of our specs and details | N/A |

| Benefits | ||

| Heat Exchanger Warranty | Longest in the industry, 15 Years (first 10 yrs full, last 5 yrs prorated) | N/A |

| Monthly Maintenance Required | Suggest that new waste oil customer’s monitor needs, every application is unique | N/A |

| Ease of Maintenance | Double Swing Doors for the industries easiest and quickest pass through cleaning (large combustion chamber and heat exchangers), Guaranteed Non-carboning pre-heater block backed with a 20 year warranty. | N/A |

| Ash Removal | ONLY As needed – dependant on severity of the oil contamination (I.E. transmission fluid once per year) | N/A |

| Temperature Rise | Axial fans with full frontal louvers, if the front of our furnace was as small as Energy Logic our heat rise would be above 200°, you get more CFM, heat throw and quicker recovery time with our design | N/A |

| Burnable Fuels | Widest range of oil viscosities in the industry, No. 2 – 90W along with synthetic after it’s been used, veggie oil’s, even gasoline 30% by tank volume | N/A |

| Product Features | Omni/Econoheat | Reznor |

|---|---|---|

| SST Heat Exchanger | 16g 304L SS crimped non-welded design | N/A |

| Low Fuel Cut Off | Optional (Rarely Requested) | N/A |

| Ash Removal Port | Large combustion chamber & heat exchangers with double swing doors, Industries easiest and fullest access for easiest and quickest cleaning and maintenance | N/A |

| System Intelligence | Optional | N/A |

| Tank Designed for Waste Oil | Tank/Stand available in 250, 350 and 500 gallons, 11 gauge steel, powder coated with tank kit/fittings | N/A |

| BTU Output | Listed on ALL of our specs and details | N/A |

| Benefits | ||

| Heat Exchanger Warranty | Longest in the industry, 15 Years (first 10 yrs full, last 5 yrs prorated) | N/A |

| Monthly Maintenance Required | Suggest that new waste oil customer’s monitor needs, every application is unique | N/A |

| Ease of Maintenance | Double Swing Doors for the industries easiest and quickest pass through cleaning (large combustion chamber and heat exchangers), Guaranteed Non-carboning pre-heater block backed with a 20 year warranty. | N/A |

| Ash Removal | ONLY As needed – dependant on severity of the oil contamination (I.E. transmission fluid once per year) | N/A |

| Temperature Rise | Axial fans with full frontal louvers, if the front of our furnace was as small as Energy Logic our heat rise would be above 200°, you get more CFM, heat throw and quicker recovery time with our design | N/A |

| Burnable Fuels | Widest range of oil viscosities in the industry, No. 2 – 90W along with synthetic after it’s been used, veggie oil’s, even gasoline 30% by tank volume | N/A |

| Product Features | Omni/Econoheat | EnergyLogic |

|---|---|---|

| Heat Exchanger | 16g 304L SS crimped non-welded design | SST? What grade of steel is SST? |

| Low Fuel Cut Off | Optional (Rarely Requested) | Standard |

| Ash Removal Port | Large combustion chamber & heat exchangers with double swing doors, Industries easiest and fullest access for easiest and quickest cleaning and maintenance | Very small opening, hard to clean |

| System Intelligence | Optional | Optional |

| Tank Designed for Waste Oil | Tank/Stand available in 250, 350 and 500 gallons, 11 gauge steel, powder coated with tank kit/fittings | Standard |

| BTU Output | Listed on ALL of our specs and details | Unavailable |

| Benefits | ||

| Heat Exchanger Warranty | Longest in the industry, 15 Years (first 10 yrs full, last 5 yrs prorated) | Only 10 Years (5 yrs full + 5 yrs pro-rated) NOT the longest in the industry. |

| Monthly Maintenance Required | Suggest that new waste oil customer’s monitor needs, every application is unique | None |

| Ease of Maintenance | Double Swing Doors for the industries easiest and quickest pass through cleaning (large combustion chamber and heat exchangers), Guaranteed Non-carboning pre-heater block backed with a 20 year warranty. | Swing out burner, one very small tube |

| Ash Removal | ONLY As needed – dependant on severity of the oil contamination (I.E. transmission fluid once per year) | 1,200 Hours |

| Temperature Rise | Axial fans with full frontal louvers, if the front of our furnace was as small as Energy Logic our heat rise would be above 200°, you get more CFM, heat throw and quicker recovery time with our design | 120° because of their very small louver opening |

| Burnable Fuels | Widest range of oil viscosities in the industry, No. 2 – 90W along with synthetic after it’s been used, veggie oil’s, even gasoline 30% by tank volume | No. 2 – 90W only |